Water is one of the most critical resources in industrial processes, and its treatment is essential not only for environmental sustainability but also for operational efficiency. In the cigarette manufacturing industry, water is heavily used in various stages of production, including cooling, cleaning, and process requirements. Managing wastewater from this industry can be challenging due to the high levels of chemical contaminants and organic pollutants present in the effluent. For industries looking to achieve a zero-liquid discharge (ZLD) status, an efficient and sustainable water treatment plant operation is key.

The Challenge: Wastewater in the Cigarette Industry

The cigarette manufacturing process produces significant amounts of wastewater that is often rich in organic matter, chemicals, and other pollutants. A major concern in treating this effluent is the high levels of Chemical Oxygen Demand (COD) and Biochemical Oxygen Demand (BOD), both of which indicate the level of pollution in water.

In one of Grinviro’s recent successful projects, a water treatment plant operation was installed at a major cigarette manufacturing facility, where the wastewater had the following characteristics:

- COD: 8,000 ppm

- BOD: 4,000 ppm

These high concentrations of pollutants posed a significant challenge, as the water had to be treated to meet strict regulatory standards before being reused or safely discharged. The target was to meet the EU Drinking Water Directive, Drinking Water Standards, and Process Water Specifications set by the International Group Companies involved in the project.

Grinviro’s Solution for Water Treatment Plant Operation: Achieving Zero Liquid Discharge (ZLD)

Grinviro’s approach to achieving ZLD in this challenging environment was multifaceted, employing advanced technologies in water treatment. Below are some key components of the sustainable treatment process that made the project successful:

1. Pre-Treatment Systems: Screening and Equalization

Before tackling the chemical and biological pollutants in the wastewater, Grinviro’s team first implemented a pre-treatment process. This stage involved screening and equalization to remove larger particles and ensure a consistent flow of water for further treatment. Equalization tanks were used to balance the water quality and flow rate, preventing shock loading on the treatment system.

2. Advanced Biological Treatment: Waste to Energy

Advanced biological wastewater treatment has become a critical solution for addressing environmental challenges while promoting sustainable energy production. Grinviro’s innovative products, BIOFLUX MBR and ANAPAK FX, play a key role in this field by utilizing advanced membrane bioreactor (MBR) technology and efficient bioremediation processes. BIOFLUX MBR combines biological filtration with a membrane system, allowing for enhanced treatment of wastewater by removing organic contaminants, suspended solids, and pathogens.

This results in high-quality effluent that can be reused or safely discharged. Meanwhile, ANAPAK FX focuses on optimizing the anaerobic processes in wastewater treatment, efficiently converting organic waste into biogas. The biogas produced can be harnessed as a renewable energy source, transforming waste into valuable energy while reducing greenhouse gas emissions. Together, these two products by Grinviro contribute to the circular economy by turning wastewater into a resource, offering both environmental and energy recovery solutions.

3. Modern Water Process for Zero Liquid Discharge

Zero Liquid Discharge (ZLD) is an advanced water treatment and wastewater management system designed to completely eliminate liquid waste. The primary objective of ZLD is to treat wastewater to a level where no liquid effluent is discharged into the environment. Through a combination of processes such as filtration, reverse osmosis, evaporation, and crystallization, ZLD systems recover water for reuse, ensuring that nearly all water used in industrial or municipal operations is recycled. This approach reduces reliance on external water sources and minimizes the impact of wastewater disposal on ecosystems.

ZLD is particularly beneficial for industries operating in water-scarce regions or those with stringent environmental regulations. By recovering and reusing water, ZLD systems help reduce the consumption of freshwater, lower operational costs related to water procurement, and minimize the risk of environmental pollution. Although implementing ZLD can be capital-intensive, it offers long-term benefits in terms of sustainability, water conservation, and regulatory compliance. As environmental awareness grows, more industries are adopting ZLD technologies as part of their commitment to reducing their environmental footprint and achieving sustainable water management practices.

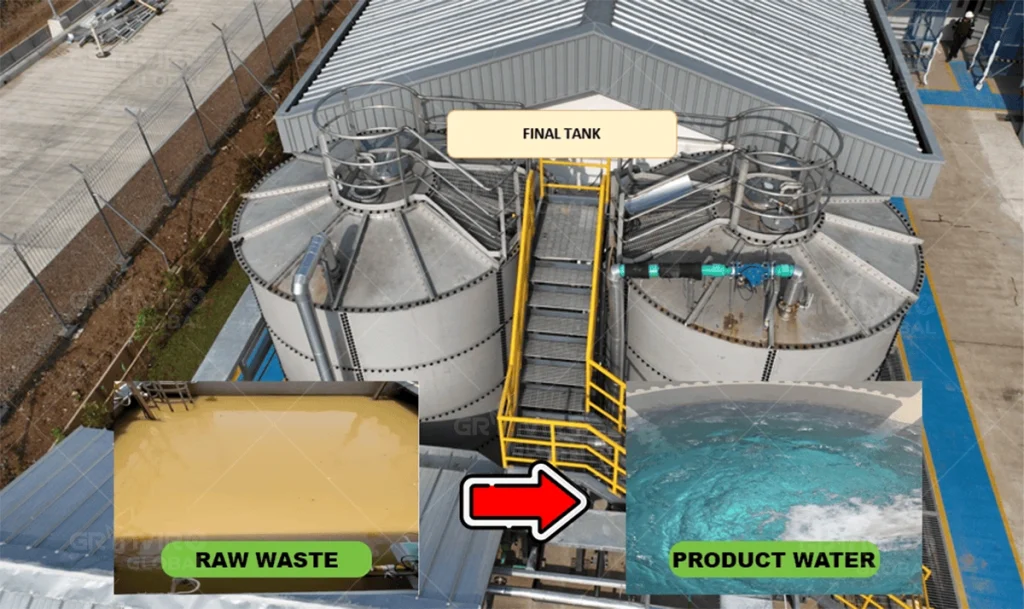

Results: Meeting International Standards

After implementing the comprehensive water treatment plant operation solution, Grinviro’s plant was able to successfully reduce the COD and BOD levels to meet international water quality standards:

- COD reduction up to 99% which was originally at 8,000 ppm to just under 20 or even 0

- BOD reduction up to 99% which was originally at 4,000 ppm to below 10 and even 0

The treated water, now purified and free of harmful contaminants, met the strict Process Water Specifications required by the International Group Company involved in the project. The result was a fully sustainable water treatment plant operation that achieved Zero Liquid Discharge and helped the cigarette manufacturer drastically reduce its environmental footprint.

Conclusion

Grinviro’s successful implementation of a sustainable water treatment plant operation in the cigarette industry highlights the effectiveness of advanced technologies in achieving Zero Liquid Discharge (ZLD) while meeting stringent international water quality standards. By combining biological treatment, membrane filtration, and effective concentrate management, the project not only ensured compliance with the EU Drinking Water Directive and other global specifications but also set a benchmark for environmental responsibility and resource conservation in industrial water management. This success showcases that with the right strategies, even complex wastewater challenges can be addressed sustainably.

Visit Us:

- 7th floor,1#Building ,No.200 Sanmen Road ,Yangpu District ,Shanghai ,China

- The Prominence Office Tower Lt. 28, Jl. Jalur Sutera Barat, Tangerang

- Jl Utama Modern Industri Blok AA No.5, Kawasan Modern Industri Cikande

- Ciputra World Office Surabaya Lt. 29, Jl. Mayjen Sungkono, Surabaya

- Pattene Business Park Blok W3a Makassar